How to Develop a Large-Scale, Wildly Successful Brand Experience

And why you need the right vendors in your corner

Feld Entertainment is one of the largest live production companies in the nation. They serve audiences of all ages through their exciting, traveling, live shows. Their lineup of spectacular shows earned them the contract from Universal Studios to develop, manage and fabricate an interactive experience for Dreamworks’ Trolls.

With a capable fabrication team in house, Feld autonomously maintains their current traveling lineup. Creating a brand new experience in less than six months however, is an added challenge given their full shop at the time. Knowing this, Feld and BeCore began the search for partners they could trust to bring Trolls The Experience to life. After portfolio presentations and shop tours, Feld chose Atomic Props to be their main fabricator for the experience.

So what qualities in a partner should you look for when activating a large brand experience? To minimize your stress, look for partners that will act as a turnkey resource for you, who can manage and execute design, production, and installation for all 3D elements in the experience. We’ve broken down each phase to highlight some of the important qualities to look for when evaluating potential partners.

Is Experienced in Large Scale Design for Events & Experiences

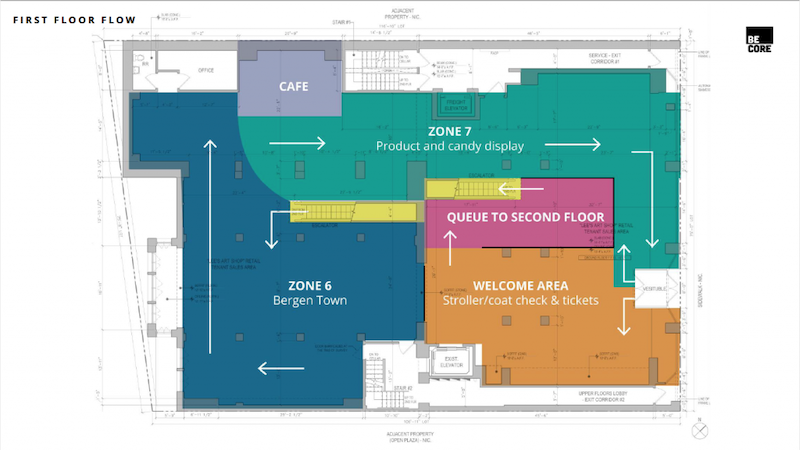

Feld had a 30,000 sq ft space picked out and general concept artwork of the experience. Creating a concrete layout of the experience was something they simply did not have the time to complete while managing other aspects of the experience. Atomic was responsible for generating the entire experience layout. We worked closely with the client as we developed the theme of each zone and traffic flow of the experience.

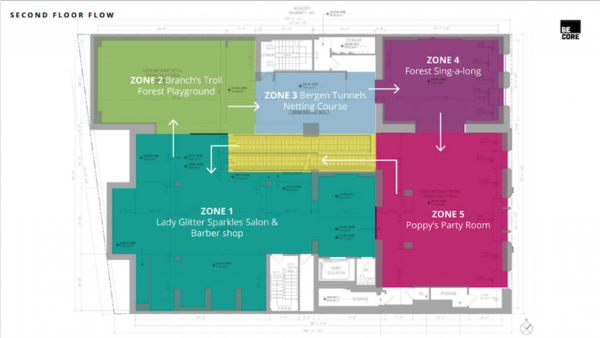

Provides Clearly Illustrated Designs & Fabrication Materials

Over 100 props needed to be designed and approved by the client prior to starting production. We provided CAD drawings of each prop that clearly illustrated what was going to be fabricated, outlined build methods, and finish levels so everyone is on the same page. Managing expectations is the number one priority for anything we fabricate. The only surprises you want are from your target audience.

Builds for the Intended Use & Longevity Needed

We don’t want to bore you with all the details of fabrication. But we do want to list a few highlights.

Everything had a design and a plan, which was then orchestrated into a master plan by our shop manager. Who was the lead on this specific aspect of the project? How do we efficiently fabricate all of these props? Are there production timelines that clash? Are there any bottlenecks? All of these things were discussed BEFORE pressing go on our CNC mill. Weekly production meetings and daily progress photo updates sent to the client kept the project rolling smoothly.

All of the licensed characters were CNC machined out of foam from 3D solid files provided by the client. Meaning, the Trolls, sing-along characters, and the Troll Tree are all exact replicas.

Can Produce “Never Done Before” Finishes and Special Effects

The finish level of these props was something we have never done before. Dang near everything was flocked adding a tactile experience to each of the pieces. Oh, and there was glitter. So. Much. Glitter.

Can’t Stop, Won’t Stop Work Ethic

Just because we put some props on a truck doesn’t mean that’s the end of our services. We sent a team from Atomic to oversee installation. At installs, our motto is, all for one and one for all. If another vendor needs assistance with their aspect of the experience, we will help because it’s the right thing to do. It technically might be ‘out of our scope of work’ but our client’s happiness and success are not.

Can React to Surprises

The best vendors plan for surprises because they happen! Last minute changes, truck delays, human error. There are surprises on every job and we are good at rolling with the punches.

If you’ve made it this far, thank you! A large scale, multi-faceted project like this is nearly impossible to cover in a single social media post. We wanted to identify some of the pain points we typically see and illustrate how Atomic alleviates them. Many people only see the magic of the final product and often don’t see the work that happens behind the curtain. Having the right team of vendors in your corner makes the work easier and the outcome greater.