Choosing The Right Fabricator

What qualities should you look for in a fabricator for your custom built experiences and 3D OOH props? How do you match the right vendor to the right project? Here are a few key questions to ask:

Do you fabricate in-house or do you sub out portions of the work?

This is a good question to ask so you know who is doing the actual work. If the work is done in another location, ask where. It is recommended you visit the shop at least once to view the operations, the team members and their process. Know the type of work that is subbed out and why.

Do you provide structural CAD drawings with every project?

Believe it or not, some fabricator vendors do not do this. It becomes very important to have this documentation especially if you plan to keep and tour the prop or activation. It tells everyone (installers, shippers, onsite labor, etc.) how many pieces the project is built in, how much each pieces weighs, how it assembles, disassembles and packs into the crates. Without this, you may as well lick your finger and stick it in the air.

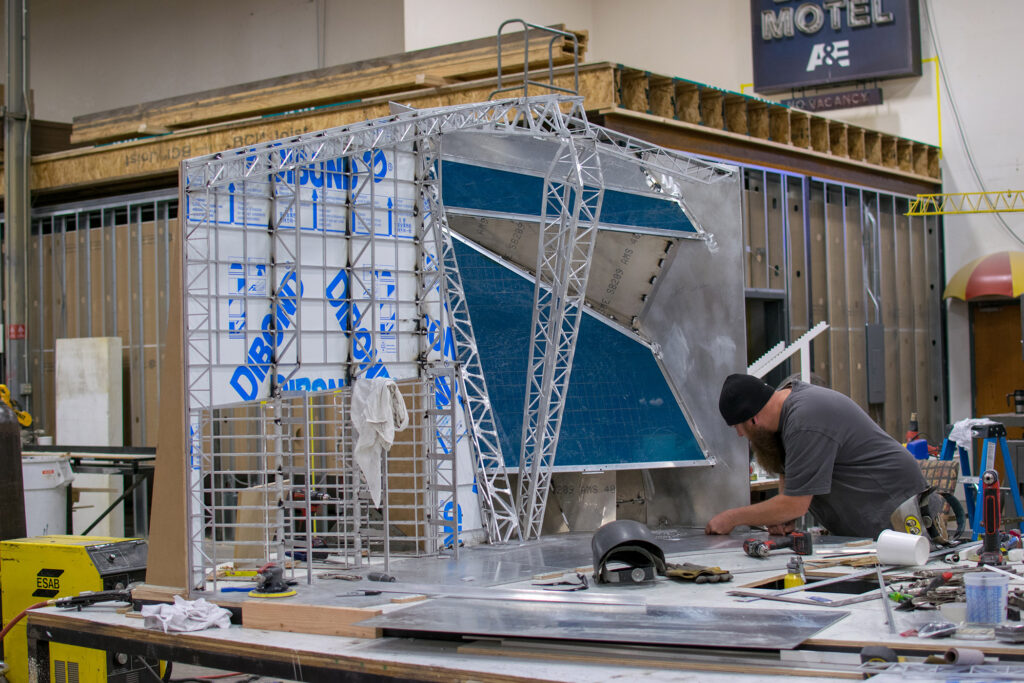

What is the experience of your staff? Are your craftsmen artists or tradesmen?

There is a big visual difference between an artist whose medium is welding vs. a welder who came from welding air conditioners. Know who is building your stuff!

What sets you apart from your competition?

There are a lot of fabricator vendors who can build what you put on paper. But what else can they do for you? What sets them apart? Match those key qualities to the project you need produced.

What is your communication and approval process?

Ask for the process to be clearly explained. I’ve seen situations where clients have not been given photos or video of the project prior to shipping and been very surprised once the pieces are installed. Surprises are not good at this stage as they aren’t likely able to be corrected.

What kind of response time should we expect?

Ask about response time to emails, estimate requests, change orders, etc. This will help you manage your client’s or your internal stakeholders expectations from the start.

How long does it take to get an estimate?

It is imperative to know this and communicate your needs to your vendors. Some of us are faster than others, so never assume response times are the same among fabricator vendors.

Are all the costs I may incur listed on the estimate?

I can’t stress this one enough. Especially if you don’t have time to read through the estimate, by all means ask the fabricator vendor to outline all the costs including those that may not be clearly listed on your estimate.

What is your average lead time?

Most fabricators will have an average lead time and have the ability to offer a rush schedule for an additional fee. Always ask what the lead time is if it’s not listed on your estimate. Nothing like selling an idea to your client and learning you can’t deliver on it.

What happens should the project cost more than what you estimated?

This is very important to know upfront. If the fabricator underestimated the project, will the fabricator charge you more? Again, another surprise no one wants!

What else is important to you when evaluating a fabricator vendor? Is it quality or experience? Is it the ability to be turn-key? Is it a specific capability? Love to hear your thoughts. Connect with me or contact me at stacy@atomicprops.com.